There are many types of air compressors that come in different sizes. Each application is unique and there is usually a correct compressor for a specific application or requirement. The right compressor, properly maintained and utilized, saves labor, energy costs, and often generates a boost in productivity. With increasing electrical rates and a trend toward smaller maintenance teams, the best choices in air compressors operate with the efficiency and reliability to work better, longer and with less maintenance. Below are several examples of air compressor technologies that are currently used.

Scroll Air Compressors: Uses two spiral elements, one stationary, one orbiting to produce oil-free, contaminant-free compressed air. Scroll compressors are extremely quiet, compact, require very little maintenance and of course are oil-free. Typical applications are Medical, Laboratory, Dental, Food and Beverage, Pharmaceutical and Electronics.

Scroll Air Compressors: Uses two spiral elements, one stationary, one orbiting to produce oil-free, contaminant-free compressed air. Scroll compressors are extremely quiet, compact, require very little maintenance and of course are oil-free. Typical applications are Medical, Laboratory, Dental, Food and Beverage, Pharmaceutical and Electronics.

Reciprocating Air Compressors: This technology employs a piston moving forward in a cylinder via a connecting rod and crankshaft. The reciprocating air compressor is extremely versatile. They can be found in the smallest auto repair shops to the largest manufacturing plants. It compresses both air and gases with very little alterations and is the only design capable of compressing air and gas to high pressures.

Reciprocating Air Compressors: This technology employs a piston moving forward in a cylinder via a connecting rod and crankshaft. The reciprocating air compressor is extremely versatile. They can be found in the smallest auto repair shops to the largest manufacturing plants. It compresses both air and gases with very little alterations and is the only design capable of compressing air and gas to high pressures.

Rotary Vane Air Compressors: Rotary vane compressors cover a wide performance range and come in dry running and oil lubricated versions. Oil lubricated rotary vanes are the standard pump in numerous industrial applications.

Rotary Vane Air Compressors: Rotary vane compressors cover a wide performance range and come in dry running and oil lubricated versions. Oil lubricated rotary vanes are the standard pump in numerous industrial applications.

The single rotor design with sliding vanes allows the use of a direct drive arrangement, without the need for belts or pulleys. Its simplistic design and proven reliability make it a viable alternative to other technologies. Its compact size also makes it an ideal choice for customized compressed air and gas applications especially in the transit industry.

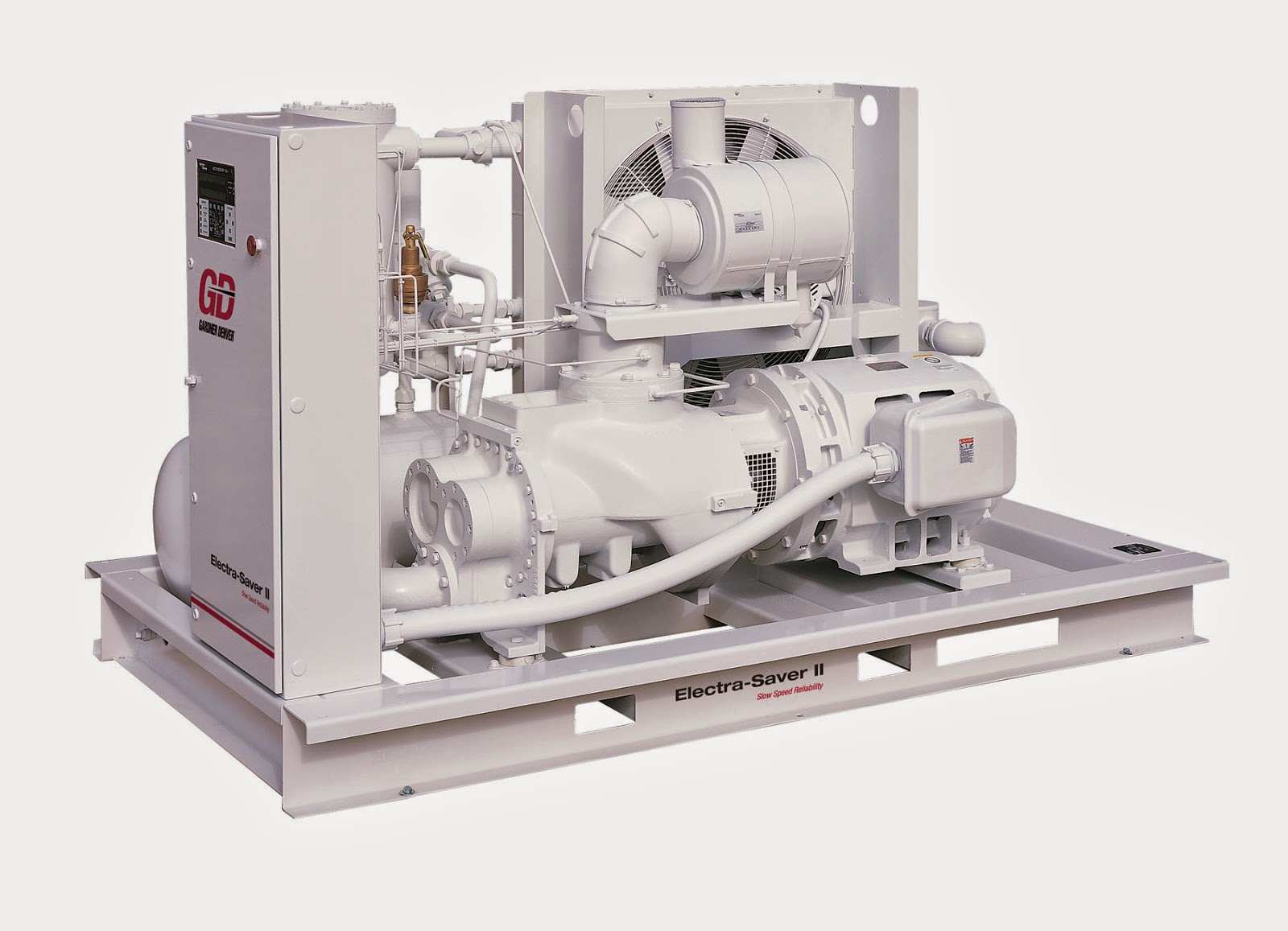

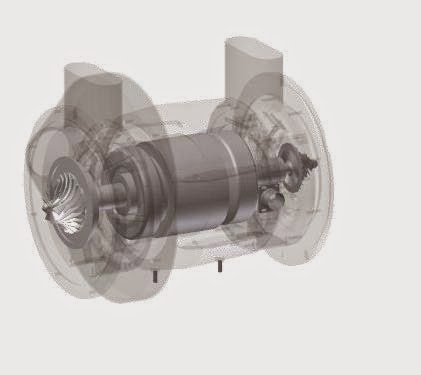

Rotary Screw Air Compressors: Rotary screw technology serves the majority of industrial applications today in the 15-500 HP range. It uses male and female rotors that move towards each other while the volume between them and the housing decreases. The screw element is not equipped with any valves and there are no mechanical forces to create any imbalance. It can therefore work at high shaft speed and combine a large flow rate with small exterior dimensions. Typical applications would be Automotive, Food and Beverage, Petrochemical, Aerospace and Electronics manufacturing.

Rotary Screw Air Compressors: Rotary screw technology serves the majority of industrial applications today in the 15-500 HP range. It uses male and female rotors that move towards each other while the volume between them and the housing decreases. The screw element is not equipped with any valves and there are no mechanical forces to create any imbalance. It can therefore work at high shaft speed and combine a large flow rate with small exterior dimensions. Typical applications would be Automotive, Food and Beverage, Petrochemical, Aerospace and Electronics manufacturing.

Centrifugal Air Compressors: Air is compressed by the mechanical action of high-speed, rotating impellers imparting velocity and pressure to the air. Approximately half of the pressure energy is developed in the impeller, with the other half achieved by converting velocity energy to pressure energy as the air speed is reduced in a diffuser and volute. Centrifugal air compressors are best suited for high flow, oil-free applications. Newer designs that use magnetic bearings and high speed motors can offer outstanding efficiency and reliability. Typical applications would be Textiles, Pharmaceuticals, Natural Gas and Chemical industries.

Centrifugal Air Compressors: Air is compressed by the mechanical action of high-speed, rotating impellers imparting velocity and pressure to the air. Approximately half of the pressure energy is developed in the impeller, with the other half achieved by converting velocity energy to pressure energy as the air speed is reduced in a diffuser and volute. Centrifugal air compressors are best suited for high flow, oil-free applications. Newer designs that use magnetic bearings and high speed motors can offer outstanding efficiency and reliability. Typical applications would be Textiles, Pharmaceuticals, Natural Gas and Chemical industries.

Cost of Ownership: There are many ways to improve compressor efficiency and reduce compressed air cost of ownership, and this doesn’t always involve investing in new equipment. Lewis Systems & Service Co., Inc. can help improve the efficiency and functionality of the entire compressed air system by performing a compressed air audit. We can help you uncover ways to improve your energy efficiency and make significant reductions in operating costs.

A note about service and maintenance: Industry figures estimate that compressed air systems can waste up to 30% of the compressed air through leaks, poor controls or lack of maintenance. In addition, compressor efficiency may degrade with age. Therefore, no matter what type of air compressor your plant has, implementing a compressed air maintenance program is essential to ensure a high level of performance over the years. Lewis Systems & Service Co., Inc. can help you design a program for your in house personnel or we can take care of all your equipment through a custom designed preventative maintenance agreement.

If you’re in need of air compressor services in Virgina or North Carolina, contact our team today at (800) 222-4553!