Once you’ve selected a quality air compressor for your business, it’s important to make sure the equipment is installed properly. Where’s the right place for it? What other equipment do you need to keep the compressor running at its best? Considering this air compressor installation guide before your machine arrives can help your air compressor perform efficiently and last as long as possible.

Top 6 Air Compressor Installation Considerations

- Location

- Ventilation

- Clearance Around Equipment

- Electrical Access

- System Configuration

- Maintenance Plan

Location

When possible, we recommend installing compressed air systems indoors, enclosed in their own clean, dry room near your end use. Keeping the compressor separate helps to control air quality, avoid overheating issues, minimize the chance of injury and reduce productivity losses from noise. Indoor systems are also not subject to the moisture and weather issues that outdoor systems face.

Ventilation

Indoor compressors need to be in a well-ventilated space. Air must be vented out of the building away from dangers like gasoline or propane fumes and paint spray filter outlets. The ventilation system should be able to turn over the CFM of the entire unit, including the compressor and dryer. This information can be found in the compressor and dryer engineering data sheets.

Clearance Around Equipment

All air compressor equipment should have a minimum of three feet of clearance on each side. This is important for free air cooling and heat exchange on a daily basis as well as maintenance in the future. Every air compressor is different, so ask your service professional how much access space will be needed above and around your particular model. They’ll need to plan for regular maintenance and removal of the motor or airend later in the service cycle.

Electrical Access

Whether indoors or outdoors, your compressor will need access to electricity. Before plugging it in for the first time, ensure that your compressor voltage is compliant with the socket to avoid blown fuses or fires.

Compressed Air System Configuration

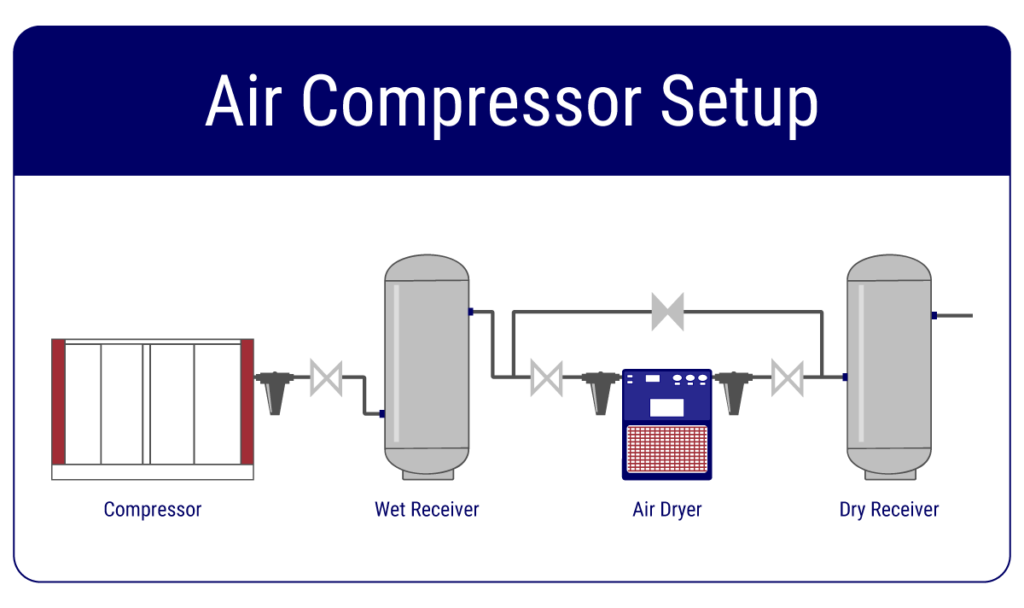

Every company’s needs are unique, but when installing a compressor system, we generally recommend that systems include a wet receiver between the compressor and air dryer and a dry receiver after the dryer. The compressor should have a moisture separator. The dryer should have a pre-filter and an after filter. And the receivers should be sized based on the CFM of the compressors. Below is a typical example of an air compressor setup diagram.

Air Compressor Maintenance Plan

The most effective way to avoid breakdowns in the future is to have a preventive maintenance plan in place when the machine is installed. To learn more about the maintenance that needs to be performed and how often, view our basic maintenance checklist.

As a professional air compressor installation company with more than 40 years of experience, Lewis Systems can help make sure your system is set up for success. Feel free to contact us at 800.222.4553 with any installation concerns or questions.