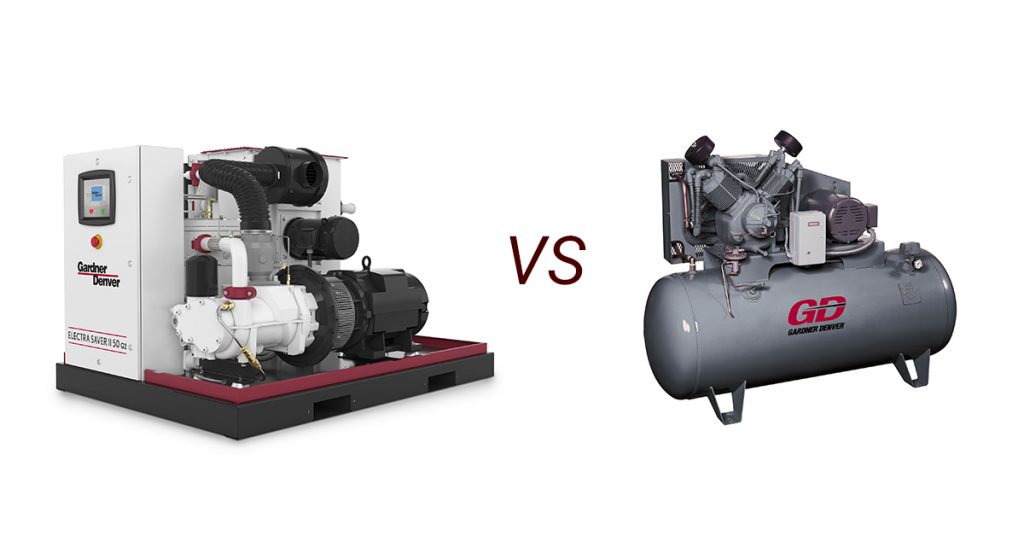

When deciding on the right air compressor for your business, it’s important to distinguish between the two main types available: the rotary screw compressor and the reciprocating/piston compressor. The first notable difference is in their operation. Rotary compressors have two screws that turn in opposite directions, trapping the air between them causing compression. Reciprocating compressors use pistons that move up and down to compress the air inside the cylinder. Although most companies have relied on the uses of reciprocating air compressors and the traditional piston model, comparing the maintenance costs, required application and individual features of both types can help you determine what’s best to help your productivity and bottom line.

Continue reading